KYHK15B™

Hard Turning Grade

KYHK15B is a ceramic grade designed for machining of hardened steel (>45 HRC), as well as finishing of cast iron and high temperature alloys. KYHK15B is ideal for continuous and varying depth of cuts and provides greater depth of cut capabilities.

The PVD coated hard turning grade, provides maximum wear resistance, and maximum tool life.

The new coating with its gold color enables easy wear progression identification.

State-of-the-art insert and coating technology provides tighter honing tolerances, leading to higher cutting edge stability, better chipping resistance, and better surface quality.

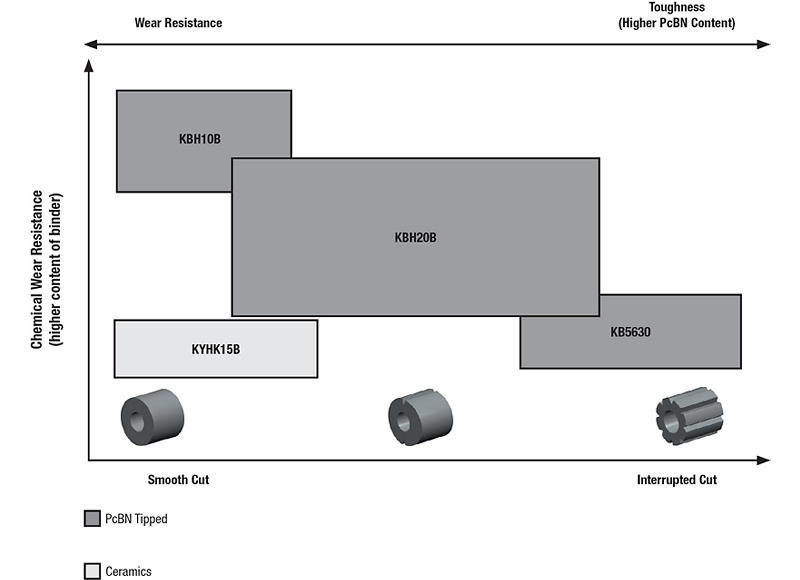

Wear Resistance and Toughness

KYHK15B can be an excellent choice to reduce insert cost while almost obtaining the same performance of PcBN. Whenever it comes to smooth-cut applications and the need for high chemical wear resistance, KBH10B™ is the best choice.

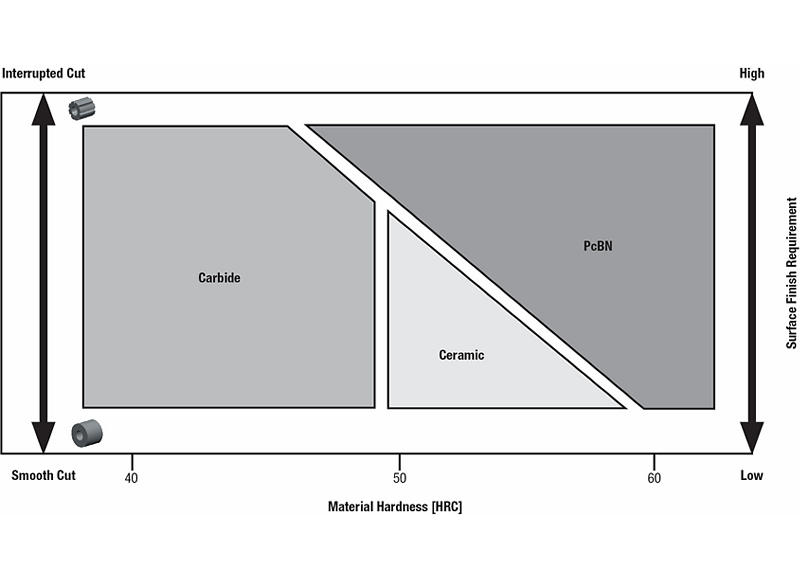

Material Hardness and Surface Finish

Depending on the surface requirement and the type of cut, the ceramic grade KYHK15B can be an economic alternative to PcBN inserts when machining hard materials >48 HRC.