Mill 4-12KT

Tangential Shoulder Milling

Tangential Shoulder Milling

- Mill 4-12KT requires up to 15% less horsepower, enabling increased feed rates, even on small machines.

- The patented insert design — featuring a triangular shaped margin — provides unprecedented stability in steel and cast iron applications.

- Excellent floor finishes due to minimal axial runout.

- With 7 grades, 7 corner radii, and depth-of-cut range up to .472″ (12mm), the program offers versatility to cover many shoulder milling applications.

Mill 4-12KT Left-Handed Inserts

For maximum stability and accuracy in custom solution slotting cutters.

Custom solution slotting cutters upon request.

View Mill 4-12KT in Action!

Challenge:

Improve cost-per-part (CPP) by increasing productivity when milling a dry roughing to finishing application.

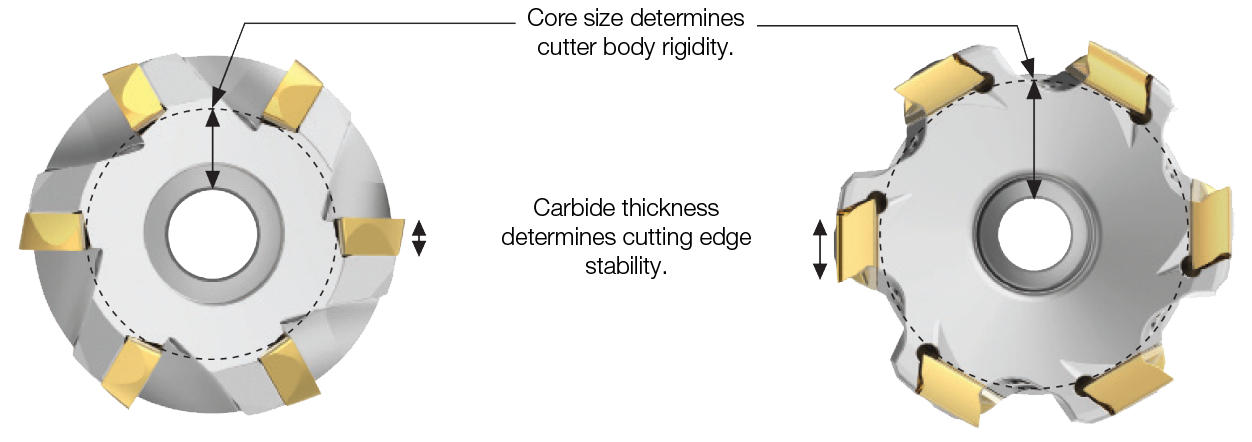

Radially Mounted

Requires large pocket; reduces the core size of the cutter.

Allows very small diameter cutter bodies.

Access to insert screw can be tough.

Tangentially Mounted

A shallow pocket allows for large core size of the cutter.

Very strong cutting edge.

Easy access to insert screw.