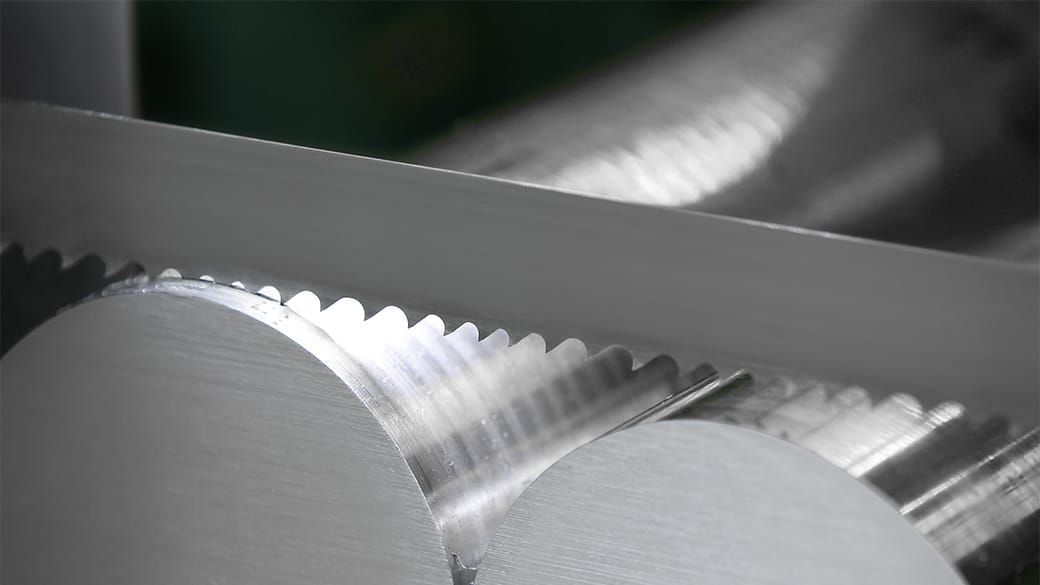

MARATHON X3000

The special band saw blade for high-tensile materials

Product level 2

Hook tooth

Profiles + Solid materials

Band witdh 27 x 0.9 – 67 x 1.6mm

Description

The special band saw blade for high-tensile materials

Applications

- High-alloy austenitic materials

- Metal as of 1000 N/mm² tensile strength

- Scaled forging ingots

Advantages

- Perfect blade-life in spite of high abrasion

- Low material loss due to plane cutting

Features

- Tooth edge made of the cutting material X3000® with positive rake angle

- High cutting edge stability and high wear resistance

- Variable tooth pitch and standard set

Size

| Dimensions | Tooth pitch in ZpZ | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width x thickness | variable | |||||||||||

| mm | Inch | 5-8 | 4-6 | 3-4 | 2-3 | 1.4-2 | ||||||

| 27 x 0.90 | 1-1/16 x 0.035 | K | K | K | K | |||||||

| 34 x 1.10 | 1-3/8 x 0.042 | K | K | K | ||||||||

| 41 x 1.30 | 1-5/8 x 0.050 | K | K | K | ||||||||

| 54 x 1.60 | 2-1/8 x 0.063 | K | K | K | K | |||||||

| 67 x 1.60 | 2-5/8 x 0.063 | K | K | K | ||||||||

| Contact length | [mm] [Inch] |

30-60 1.2-2.4 |

50-100 2-3.9 |

80-170 3.1-6.7 |

150-300 5.9-11.8 |

250-550 9.8-21.6 |

||||||

K = Hook tooth

Technical Data

- Rust-proof and acid-resistant steels (ferretic)

- Nickel-based alloys

- Titanium / titanium alloys

- Tempered steels (over 1000 N/mm² / 32 HRC)

- Duplex and heat-resistant steels

- Aluminium bronzes